Are you looking to elevate your inspection strategy? If so, you’ve come to the right place! In this blog post, we will be exploring advanced third-party inspection techniques that can help you create an effective and efficient system of checks and balances. We’ll look at the various ways third-party inspectors can make sure your products, services, and processes meet safety and quality standards. From conducting regular testing and audits to utilizing specialized technologies, we’ll dive into the specifics of how third-party inspections can be used to ensure your standards are being met. So let’s get started!

The Importance of Third-Party Inspection Services

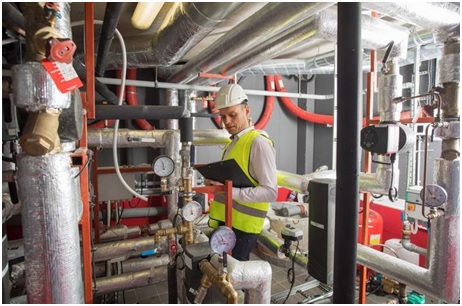

When it comes to ensuring the quality and safety of your products or services, there’s nothing more important than third-party inspection services. By partnering with a reputable third-party inspection provider, you can have peace of mind knowing that your operations are being closely monitored by trained professionals who are impartial and unbiased.

Why is third-party inspection so crucial? First and foremost, it helps to ensure that your products or services meet all relevant industry standards and regulations. This is especially important if you’re operating in a highly regulated industry like healthcare, aerospace, or automotive. By working with a third-party inspection provider, you can be confident that your products meet all required specifications and will perform as intended.

Another key benefit of inspection is that it provides an extra layer of protection against potential safety issues or product defects. By identifying issues early on, you can take corrective action before any harm is done to consumers or your brand reputation. Read more about Download Threads Video.

But inspection isn’t just about ensuring compliance and safety – it’s also about driving innovation and continuous improvement. By partnering with an inspection provider, you gain access to valuable insights and data that can help you identify areas for improvement and optimize your operations.

Common Third-Party Inspection Techniques

Third-party inspection services have become an essential part of industries around the world. They are designed to provide an impartial and unbiased evaluation of the quality, safety, and compliance of products, systems, and services. These inspections are typically carried out by independent organizations with the necessary expertise and experience to ensure that industry standards are being met.

Here are some common third-party inspection techniques used by inspectors:

- Visual Inspection: This involves the inspector visually examining the product or service to determine if it meets the necessary standards. This inspection technique is ideal for products that can be easily inspected with the naked eye.

- Dimensional Inspection: This inspection technique involves measuring the dimensions of a product or system to ensure that it meets the required specifications. The inspector will use calibrated measuring instruments to obtain accurate measurements.

- NDT (Non-Destructive Testing): This technique involves inspecting a product or system without damaging it. NDT methods include ultrasonic, magnetic particle, liquid penetrant, and radiographic testing. NDT is ideal for identifying defects or discontinuities in materials without damaging the product or system.

- Documentation Review: This involves the inspector reviewing documents, reports, and records related to the product or system. The inspector will assess the accuracy, completeness, and consistency of the documentation and ensure that it meets industry standards.

While these inspection techniques are effective, they have limitations. For instance, visual inspection may not be effective for detecting internal defects in a product or system. Similarly, NDT may not be suitable for identifying surface-level defects. Therefore, advanced inspection techniques are necessary for more accurate results.

Advanced Inspection Techniques: An Overview

When it comes to quality control services basic techniques can only take you so far. That’s why advanced inspection techniques have been developed, designed to elevate your inspection strategy and provide you with more accurate and insightful results. In this section, we’ll take a look at some of the most innovative techniques being used by leading third-party inspection providers.

One such technique is laser scanning. By using a laser scanner, inspectors can capture incredibly detailed 3D images of equipment, structures, and other assets. These images can then be used to identify areas of concern, such as corrosion or cracks, that may have been missed by traditional inspection methods. Laser scanning is a non-destructive technique that is particularly useful for inspecting hard-to-reach areas, making it an ideal choice for the oil and gas industry.

Another advanced inspection technique that is gaining popularity is drone inspection. Drones equipped with high-definition cameras can be used to inspect pipelines, wind turbines, and other assets from above, providing inspectors with a bird’s eye view of the situation. This not only makes inspections safer, but it also allows for more comprehensive inspections in a shorter amount of time.

For those looking to take things to the next level, AI-powered inspection techniques offer incredible potential. By analyzing vast amounts of data, machine learning algorithms can quickly and accurately identify potential issues before they become serious problems. This can save companies time and money, while also improving safety and reducing downtime.

Finally, real-time data collection and analysis techniques are also being used to great effect by third-party inspection providers. By using sensors to gather data, and then analyzing that data in real-time, inspectors can quickly identify any potential issues and take corrective action before any damage is done. This not only helps to keep equipment running smoothly but can also help to prevent catastrophic failures that can lead to expensive downtime and repairs.

High-Tech Inspection Tools for More Accurate Results

Gone are the days of traditional inspection methods that relied on visual analysis alone. Thanks to modern technology, inspection providers now have access to high-tech tools that provide more accurate results than ever before.

One of the most common high-tech tools used in inspections is non-destructive testing (NDT) equipment. These devices use various techniques such as ultrasonic testing, x-ray inspection, and magnetic particle inspection to identify internal defects in a product or structure without causing damage.

For instance, ultrasonic testing is particularly effective in identifying flaws in welds or detecting any abnormalities in materials. This technique involves emitting high-frequency sound waves and analyzing their reflections to determine the thickness, composition, and integrity of the material being tested.

In addition to NDT equipment, advanced inspection tools also include laser scanning and 3D modeling technology. These tools enable inspectors to create detailed digital models of products and structures, which can be used for precise measurements and comparisons.

By using these tools, third-party inspection providers can significantly reduce the time and resources required for inspections while also improving the accuracy and reliability of their results. This translates to better quality products, increased safety, and ultimately, better business outcomes.

Moreover, using these advanced tools helps in gaining customer trust as the customer gets a better view of their product and structure and in turn, builds a healthy and transparent relationship with the third-party inspection providers.

However, it’s essential to note that using these tools requires expertise and training to ensure accurate and reliable results. Therefore, it’s essential to partner with an experienced inspection provider that has a proven track record in using these high-tech tools.

So, if you want to take your inspection strategy to the next level, it’s time to explore the world of high-tech inspection tools and their benefits. After all, your products and structures deserve the best inspection possible.

AI-Powered Inspection Techniques: The Future of Third-Party Inspection

When it comes to inspection services, AI-powered techniques are on the rise and expected to revolutionize the industry. Using artificial intelligence technology to augment or replace human inspectors in some instances, these advanced techniques can quickly analyze and process large amounts of data, increasing inspection accuracy and efficiency.

AI-powered inspection techniques use machine learning algorithms to process images, sound, and vibration data, improving defect detection and predictive maintenance in equipment, machinery, and structures. By detecting anomalies and identifying patterns, these techniques help inspection providers and their clients to anticipate and prevent potential issues, thereby reducing downtime, improving safety, and saving money in the long run.

In addition, AI-powered inspection techniques can operate in harsh or dangerous environments where it may not be safe for humans to do so. Robots equipped with sensors and cameras can crawl or fly to collect data and transmit it back to the control center. This not only minimizes the risks to human life but also reduces the cost of hiring, training, and retaining qualified personnel.

Furthermore, AI-powered inspection techniques provide real-time data analysis and decision-making, enabling instant reporting and response to any issues. This enhances communication between the inspector, client, and repair teams, facilitating faster resolution of any problems that may arise. This aspect is particularly valuable in industries where time is of the essence, such as aviation, construction, and energy.

AI-powered inspection techniques also offer unparalleled accuracy and precision in detecting faults, defects, and irregularities. The ability of machine learning algorithms to identify patterns, anticipate wear and tear, and diagnose potential problems in their early stages allows for targeted and efficient maintenance. This helps to extend the life of equipment, machinery, and structures, as well as reducing costs associated with unnecessary maintenance.

Conclusion

In conclusion, third-party inspection services are an integral part of many industries. These services not only ensure that products and services are up to par but also provide an objective assessment of their quality. With the advent of new technologies and advanced inspection techniques, it has become possible to achieve greater accuracy and precision in the inspection process. From high-tech inspection tools to AI-powered techniques, these new technologies are revolutionizing the inspection process and setting the stage for the future of third-party inspection services.

Whether you are in manufacturing, construction, or any other industry that relies on third-party inspection services, it is crucial to select the right provider. Choose a provider that understands your needs, has a deep understanding of your industry, and employs advanced techniques to deliver the most accurate results.